Why Hydraulic Hoses and Fittings Are Important?

High-pressure fluid flow is very important for hydraulic systems that power machines in fields like construction, mining, manufacturing, and farming. The hydraulic hose with fittings is the most important aspect of these systems. It makes sure that fluids move safely and quickly between parts. When chosen and installed appropriately, these parts work well for a long time and lower the chance of system failure.

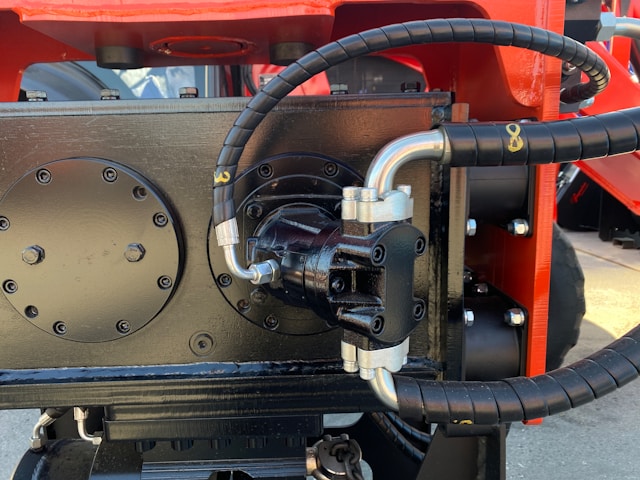

Hydraulic hoses are flexible tubes that carry pressurised hydraulic fluid, and the fittings connect the hoses to other sections of the system. This pair needs to be able to tolerate a lot of pressure, fast flow rates, and tough operating conditions. A little leak or wrong connection might cause the system to lose pressure, work less efficiently, or even cause dangerous equipment problems. That’s why it’s not simply a good idea to use high-quality hoses and precise fittings; it’s a must. Buying the appropriate parts for your machines or fleet will cut down on downtime, boost performance, and make everything safer overall.

Things to Think About When Picking a Hydraulic Hose with Fittings

To choose the right hydraulic hose with fittings, you need to know what your system needs. Pressure rating, temperature range, fluid compatibility, hose size, and bend radius are all important factors that affect how well something works. If you don’t take any of these into account, you could wear them out too soon or have a catastrophic collapse. Crimp fittings, reusable fittings, and push-to-connect designs are the most popular types of hydraulic hose fittings. Each type has its own use and is best for certain sorts of hoses and uses. For example, crimp fittings provide a safe, permanent way to connect things and are often used in high-pressure systems. On the other hand, fittings that can be used again are great for repairs and maintenance that need to be done on site.

Along with making sure the hose and fitting requirements are correct, you also need to think about where the equipment will be used. For example, machines that are exposed to very high or low temperatures, chemicals, or wear and tear will need hoses with extra protective layers and fittings that won’t rust. Top providers have a variety of hose assemblies that have already been tested for safety and performance. This saves you time during installation and lowers the danger of human mistake. Some even offer custom hose assembly services to make sure the hoses fit well for different uses.

How hydraulic hoses help the whole system work better?

The efficiency of your whole system depends on the quality and condition of the hydraulic hoses. A hose and fitting system that fits well can greatly lower fluid resistance, keep dirt out, and keep pressure steady throughout the machine. This protects important parts like pumps, cylinders, and motors from stress and makes them use less energy. To maintain your hoses in good shape, you need to do regular maintenance. Checks should be done on a regular basis to look for cracks, bulges, leaks, or other signs of wear. It’s also a good idea to keep an eye out for any symptoms of corrosion or fittings coming loose. Replacing hoses that are worn out or broken right away will keep bigger problems from happening later. Using high-quality hydraulic oil makes your hose assemblies last even longer. Using clean, high-quality oil helps both the hose and fittings work better by reducing wear and tear on the inside and keeping dirt from building up.

How to Find a Good Supplier of Hoses and Fittings?

If you need to replace just one hose or outfit a whole fleet, a reliable hydraulic parts provider can help you make the correct selections. Find a company that sells a lot of hoses and fittings in different lengths, diameters, materials, and pressure ratings. They should also be able to put together and test unique hose arrangements that are made just for your equipment. Another key service is technical support. A knowledgeable provider will help you prevent problems with compatibility and give you advice based on your machinery, industry, and working conditions. Some vendors also offer mobile hose replacement or emergency repair services, which can be a big help in the field. Your systems will work more safely, efficiently, and reliably if you use the suitable hydraulic hose with fittings and take care of them properly. This will keep your operations going and cut down on expensive downtime.